Tamping station

Turn everyday espresso tools into a clean, functional layout.

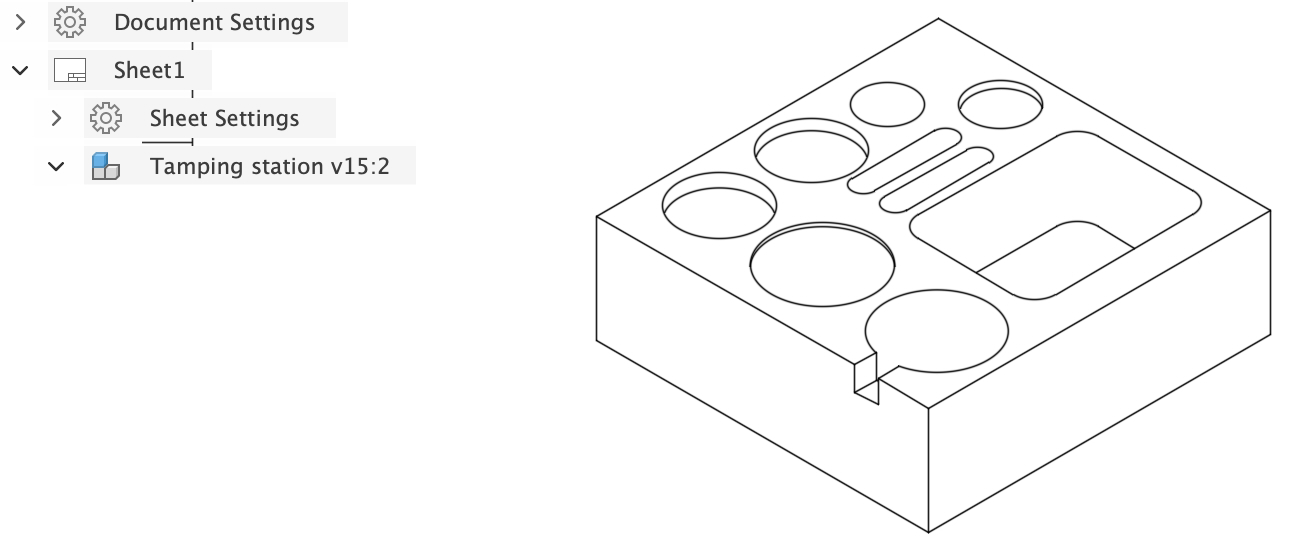

I wanted to find a better way to organize the coffee equipment used with our espresso machine. We had ended up placing everything on top of the machine, which quickly became cluttered, and the tools also became hot from the heat. Inspired by designs I found online, I decided to create a tamping station. The station would organize the equipment while also providing a stable surface for tamping espresso in the portafilter, eliminating the need to balance it by hand. Rather than ordering a tamping station online, I wanted to design and build one myself. I began the process in Fusion 360.

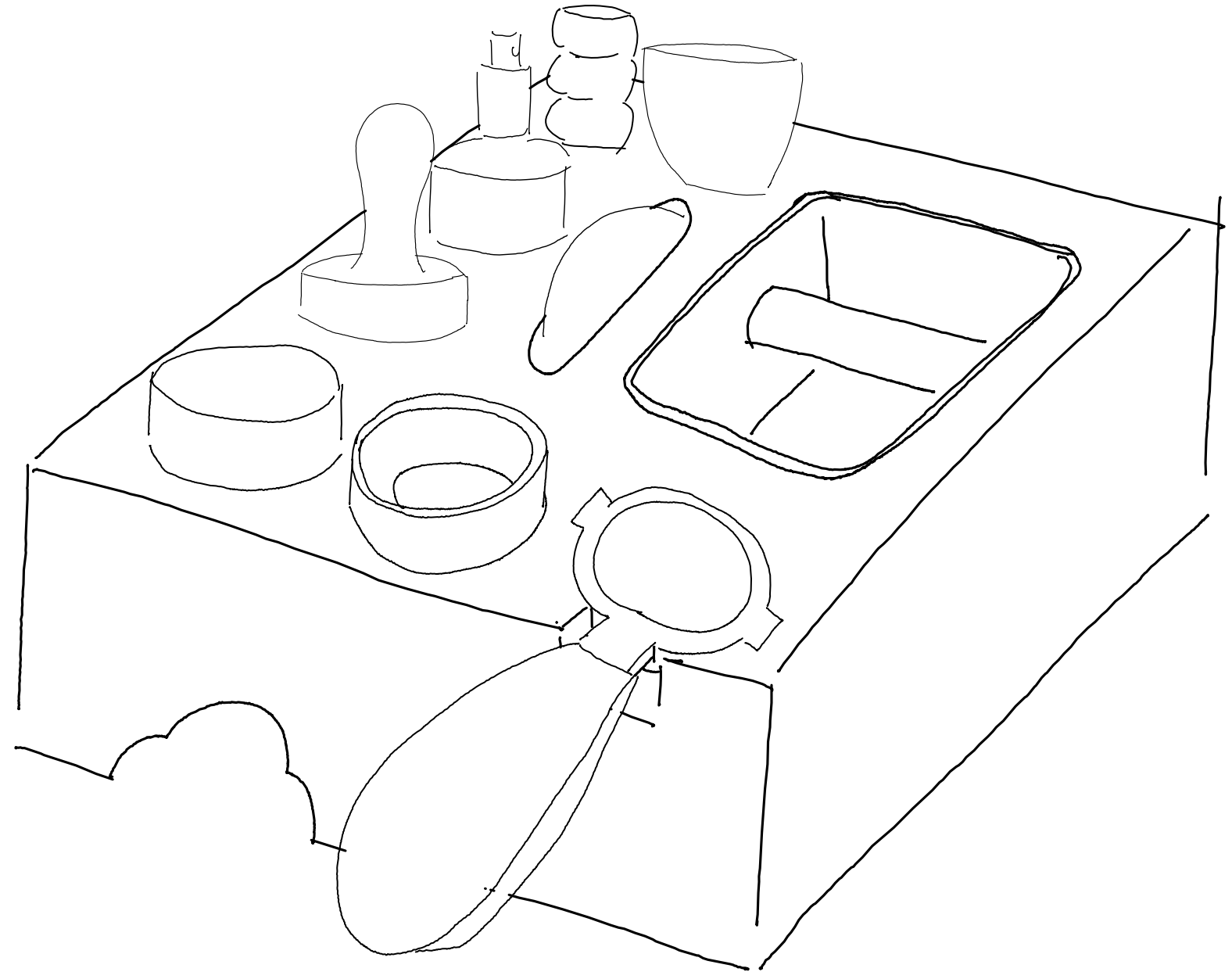

Alongside the digital design, I explored how the station would work in real life, especially when determining the overall size and proportions of the station.

I later found a listing on Finn for a large piece of ash wood. After purchasing it, I learned that the tree itself originated from Trondheim, which made the project even more meaningful.

We began by cutting the wood down to approximately the size needed for the station. However, this process presented several challenges. Ash is a very hard wood, and it was difficult to find tools suitable for working with it. As a result, much of the initial work involved manual sawing to reduce the block to a more manageable size.

.jpg)

Once the piece was easier to handle, larger equipment was used to achieve straighter cuts. Eventually, all edges were squared, but the thickness of the wood was still uneven. To solve this, we sought help from the industrial workshop at NTNU, where the thickness was made uniform.

With a flat and even surface, the block was now ready for milling. I tested the layout by placing all the coffee equipment on the wood to evaluate spacing and functionality.

.jpg)

Some essential espresso tools were still missing, so I made them myself. I threw a dosing cup in ceramic, designed to hold 15 grams of espresso beans. The cup features a small spout to make it easier to pour the beans into the grinder.

.jpg)

I also turned a wooden handle for a WDT tool (Weiss Distribution Technique), which is used to break up clumps in ground coffee for more even extraction. The needles were added afterward, and a dedicated hole was designed in the tamping station to store the tool.

Once both the wooden block and all accompanying tools were ready, the milling process began. A CNC machine was used to cut out the slots and recesses based on the measurements and drawings from Fusion 360.

The measurements taken from the coffee equipment were quite precise, but minor adjustments were still necessary. Each hole was milled individually and adjusted as needed to ensure a perfect fit.

The final and largest recess posed a challenge, as it was deeper than the CNC machine’s maximum cutting depth of 35 mm. Since the box required a depth of 54 mm, multiple holes were drilled to the maximum depth, and the remaining material was removed using a chisel.

After fitting the final component, the tamping station was complete. The finished result can be seen here.